Improving Natural Rubber

Natural Rubber Reimagined: Boosting Crack Resistance for Greater Sustainability

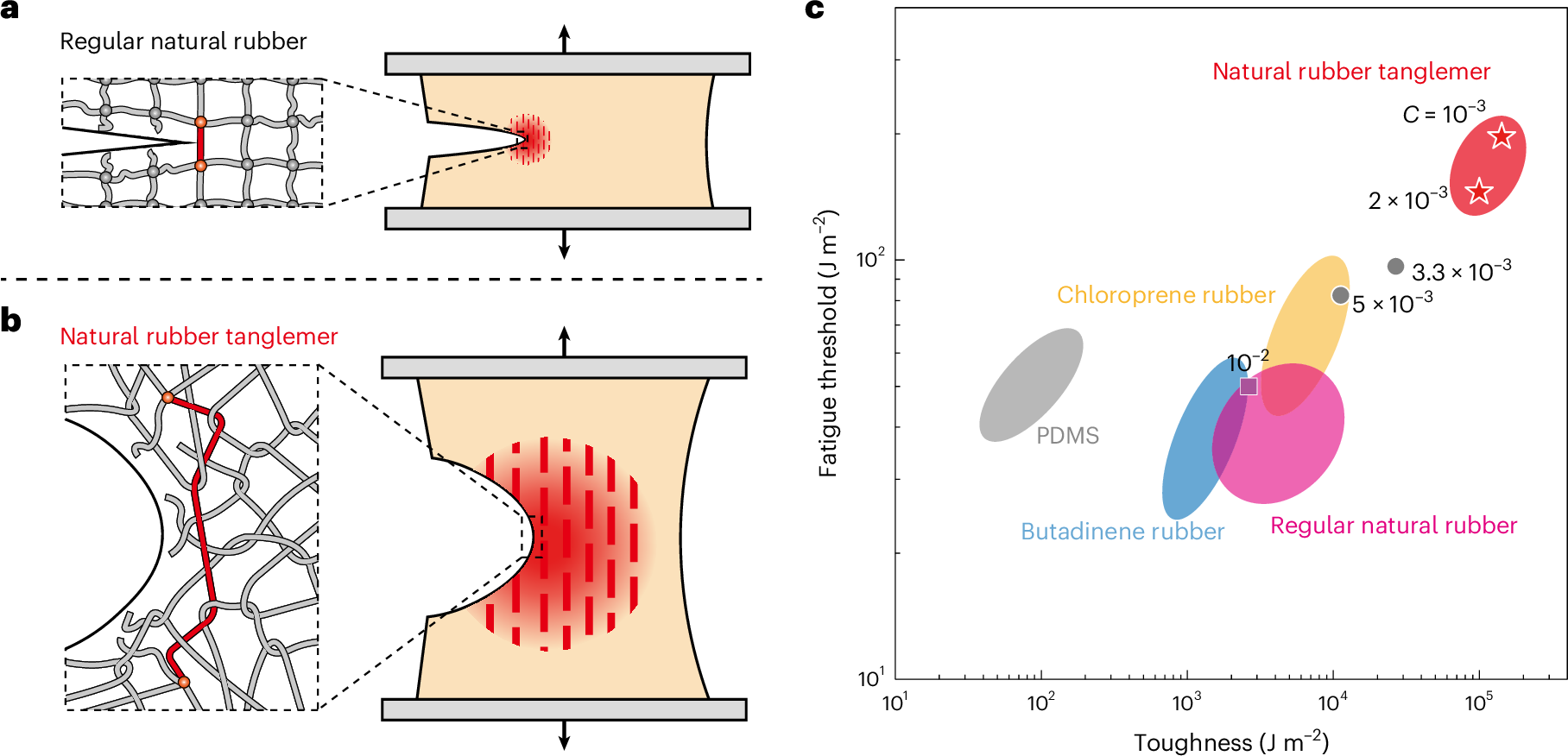

New research suggests that by reprocessing natural rubber latex without the traditional high-intensity mixing that shortens polymer chains, scientists can create a more durable material called a tanglemer. This approach, which preserves long polymer chains to form dense entanglements with sparse crosslinks, markedly improves resistance to crack growth. Results indicate potential benefits for extending the service life of products like tires, belts, and hoses, thereby enhancing sustainability by reducing polymer waste.

The Challenge with Conventional Natural Rubber Processing

Natural rubber, derived from the Hevea brasiliensis tree, is a bio-elastomer with an annual production of about 15 million tonnes. Its long, regular polymer chains contribute to superior performance, but standard manufacturing often degrades these qualities. Typically, latex is dried into blocks and mixed with additives using intense machinery like internal mixers or roll mills. This mastication process breaks down the long chains into shorter ones, necessitating denser crosslinks to form a stable network.

In such regular networks, stress at a crack tip deconcentrates over short polymer strands, and strain-induced crystallization (SIC)—a process where stretched polymers align into crystals—occurs in limited volumes. This results in a fatigue threshold (the energy level below which cracks do not grow under cyclic loading) of around 50 J m⁻² and toughness (resistance to fracture under monotonic loading) of about 10⁴ J m⁻². As the paper notes, these limitations shorten product lifespans and contribute to environmental issues like polymer pollution.

A Novel Approach: Creating the Tanglemer

To address these drawbacks, the researchers developed a method that avoids mastication, allowing long polymers to entangle densely via thermal motion before sparse crosslinking. Specifically, they dissolved dicumyl peroxide (DP), a crosslinking agent, in toluene and mixed it with natural rubber latex. After stirring for six hours, the mixture forms a single layer as polymers absorb the solution. The blend is then cast into a film at room temperature, where water and toluene evaporate, and polymers from adjacent particles entangle and endlink through non-rubber components.

“We used a low-intensity processing method, based on latex processing methods, that preserved the long polymer chains.” - Guodong Nian

Subsequent hot-pressing at 140 °C for three hours breaks temporary endlinks, enables further entanglement, and activates DP to form sparse crosslinks. The crosslink density (C), defined as the molar ratio of crosslinks to polymer repeat units, is kept low—ranging from 10⁻³ to 10⁻². At C = 10⁻³, entanglements outnumber crosslinks by about an order of magnitude, creating the tanglemer.

This process, as described by lead researcher Zhigang Suo and colleagues, decouples modulus (stiffness) from fatigue threshold, maintaining high modulus while amplifying crack resistance.

Key Findings: Enhanced Mechanical Properties

Testing revealed significant improvements in the tanglemer's performance. Under uniaxial tension, networks with lower C showed consistent modulus around 1 MPa, set primarily by entanglements rather than crosslinks. Hysteresis (energy loss during loading-unloading cycles) remained low (<20%) at moderate stretches, indicating low chain friction.

At higher stretches, SIC amplified: the tanglemer achieved higher crystallinity (up to ~30%) compared to regular networks (~15%), as confirmed by wide-angle X-ray scattering (WAXS). This extends SIC over larger volumes, enhancing energy dissipation.

Under cyclic loading, the fatigue threshold rose from ~50 J m⁻² in regular rubber to ~200 J m⁻² in the tanglemer, following the Lake-Thomas scaling where threshold scales inversely with the square root of C. Notably, this overcomes the modulus-threshold conflict, as modulus plateaus while threshold increases.

For monotonic loading, toughness exceeded 10⁵ J m⁻², with stable crack growth limits up to 2 mm—ten times that of regular rubber. In extreme tests, stretched tanglemers survived multiple blade cuts and held heavy loads without fracturing, outperforming other elastomers like PDMS or SEBS.

“We imagined that the properties would be enhanced maybe twice or three times, but actually they were enhanced by one order of magnitude. - Zheqi Chen

| Property | Regular Natural Rubber (C ≈ 10⁻²) | Tanglemer (C = 10⁻³) |

|---|---|---|

| Fatigue Threshold (J m⁻²) | ~50 | ~200 |

| Toughness (J m⁻²) | ~10⁴ | >10⁵ |

| Modulus (MPa) | ~2 | ~1 |

| Maximum Crystallinity (%) | ~15 | ~30 |

These results indicate that long strands deconcentrate stress over greater distances and enlarge SIC zones, synergizing to boost durability.

Future Implications and Challenges

The tanglemer holds promise for applications in gloves, prophylactics, and reinforced products like tires, potentially reducing waste and emissions.

"Improving crack resistance will extend the material’s service lifetime and therefore improve its sustainability" - Guodong Nian