Natural PFAS Filter

Water contamination by the chemicals used in today’s technology is a rapidly growing problem globally. A recent study by the U.S. Centers for Disease Control found that 98 percent of people tested had detectable levels of PFAS, a family of particularly long-lasting compounds also known as “forever chemicals,” in their bloodstream.

A new filtration material developed by researchers at MIT might provide a nature-based solution to this stubborn contamination issue. The material, based on natural silk and cellulose, can remove a wide variety of these persistent chemicals as well as heavy metals. And, its antimicrobial properties can help keep the filters from fouling.

The findings are described in the journal ACS Nano, in a paper by MIT postdoc Yilin Zhang, professor of civil and environmental engineering Benedetto Marelli, and four others from MIT.

PFAS chemicals are present in a wide range of products, including cosmetics, food packaging, water-resistant clothing, firefighting foams, and antistick coating for cookware. A recent study identified 57,000 sites contaminated by these chemicals in the U.S. alone. The U.S. Environmental Protection Agency has estimated that PFAS remediation will cost $1.5 billion per year, in order to meet new regulations that call for limiting the compound to less than 7 parts per trillion in drinking water.

Contamination by PFAS and similar compounds “is actually a very big deal, and current solutions may only partially resolve this problem very efficiently or economically,” Zhang says. “That’s why we came up with this protein and cellulose-based, fully natural solution,” he says.

“We came to the project by chance,” Marelli notes. The initial technology that made the filtration material possible was developed by his group for a completely unrelated purpose — as a way to make a labelling system to counter the spread of counterfeit seeds, which are often of inferior quality. His team devised a way of processing silk proteins into uniform nanoscale crystals, or “nanofibrils,” through an environmentally benign, water-based drop-casting method at room temperature.

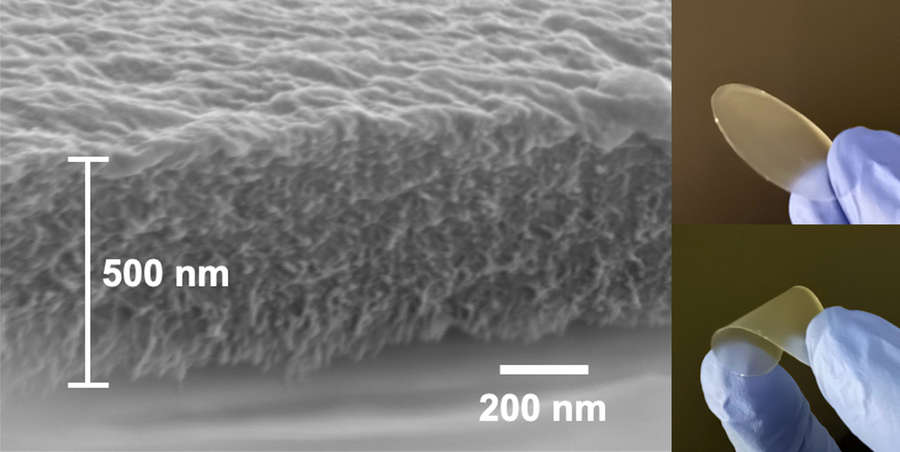

Zhang suggested that their new nanofibrillar material might be effective at filtering contaminants, but initial attempts with the silk nanofibrils alone didn’t work. The team decided to try adding another material: cellulose, which is abundantly available and can be obtained from agricultural wood pulp waste. The researchers used a self-assembly method in which the silk fibroin protein is suspended in water and then templated into nanofibrils by inserting “seeds” of cellulose nanocrystals. This causes the previously disordered silk molecules to line up together along the seeds, forming the basis of a hybrid material with distinct new properties.

By integrating cellulose into the silk-based fibrils that could be formed into a thin membrane, and then tuning the electrical charge of the cellulose, the researchers produced a material that was highly effective at removing contaminants in lab tests.

The electrical charge of the cellulose, they found, also gave it strong antimicrobial properties. This is a significant advantage, since one of the primary causes of failure in filtration membranes is fouling by bacteria and fungi. The antimicrobial properties of this material should greatly reduce that fouling issue, the researchers say.

“These materials can really compete with the current standard materials in water filtration when it comes to extracting metal ions and these emerging contaminants, and they can also outperform some of them currently,” Marelli says. In lab tests, the materials were able to extract orders of magnitude more of the contaminants from water than the currently used standard materials, activated carbon or granular activated carbon.

While the new work serves as a proof of principle, Marelli says, the team plans to continue working on improving the material, especially in terms of durability and availability of source materials. While the silk proteins used can be available as a byproduct of the silk textile industry, if this material were to be scaled up to address the global needs for water filtration, the supply might be insufficient. Also, alternative protein materials may turn out to perform the same function at lower cost.

Initially, the material would likely be used as a point-of-use filter, something that could be attached to a kitchen faucet, Zhang says. Eventually, it could be scaled up to provide filtration for municipal water supplies, but only after testing demonstrates that this would not pose any risk of introducing any contamination into the water supply. But one big advantage of the material, he says, is that both the silk and the cellulose constituents are considered food-grade substances, so any contamination is unlikely.

“Most of the normal materials available today are focusing on one class of contaminants or solving single problems,” Zhang says. “I think we are among the first to address all of these simultaneously.”

“What I love about this approach is that it is using only naturally grown materials like silk and cellulose to fight pollution,” says Hannes Schniepp, professor of applied science at the College of William and Mary, who was not associated with this work. “In competing approaches, synthetic materials are used — which usually require only more chemistry to fight some of the adverse outcomes that chemistry has produced. [This work] breaks this cycle! ... If this can be mass-produced in an economically viable way, this could really have a major impact."